WHAT IS ATEX CETIFICATION?

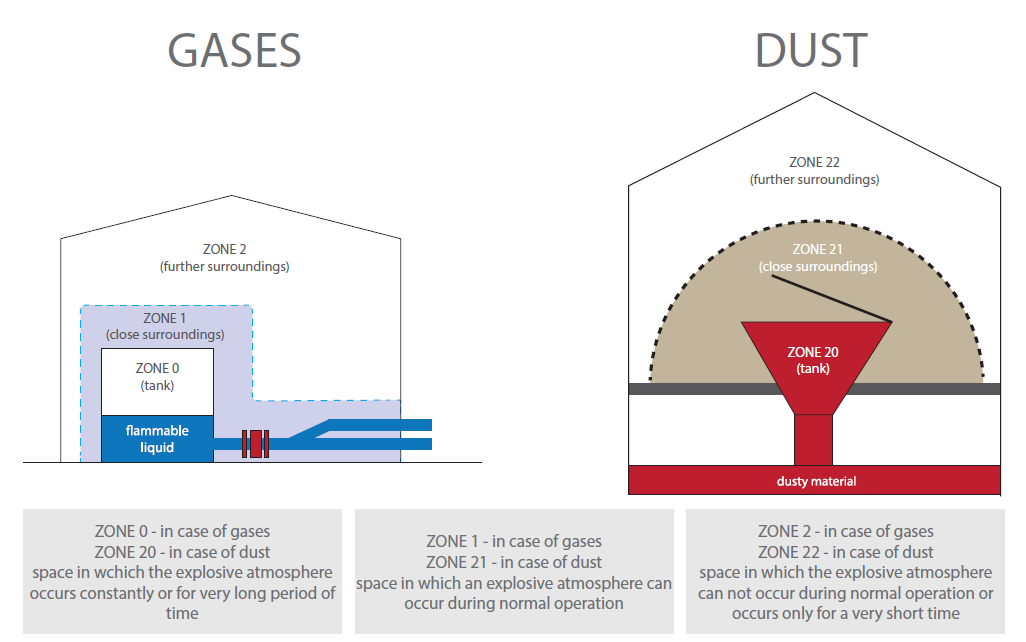

EXPLOSION HAZARD ZONES

As a zone of explosion hazard, one should understand the space in which mixtures of gases, vapors, mists and / or flammable dusts with air can occur.

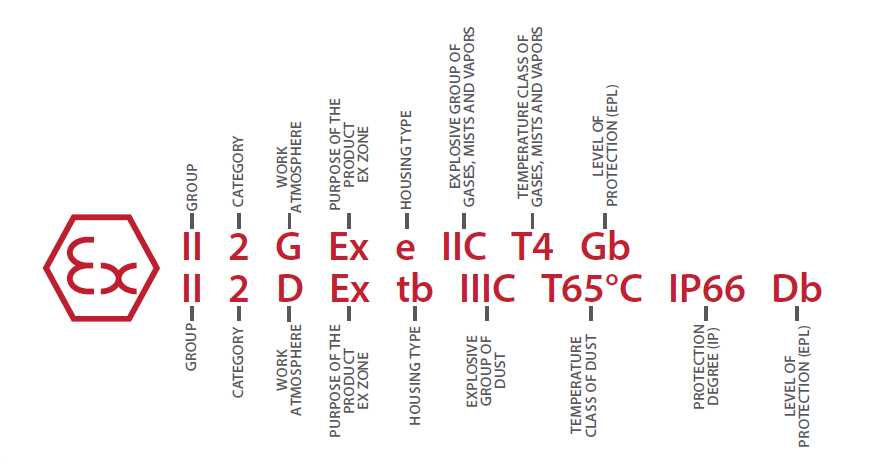

EXAMPLE OF THE EX MARKING:

Description of the example marking:

Explosion-proof luminaire designed to work in places where, during normal operation, an explosive atmosphere may occur containing a mixture of flammable substances in the form of gas, vapor, mist or dust with air. Explosion-proof protection was provided through a reinforced housing. The device can be used in the vicinity of gases classified as so-called a hydrogen group (e.g. acetylene, hydrogen) whose auto-ignition temperature is higher than 135 °C. The maximum surface temperature of the product does not exceed 65 °C. The luminaire has been protected against dust penetration into its interior due to its high IP66 protection rating and can be used in the vicinity of all types of combustible dust (including conductive ones with an electrical resistivity lower than 106Ω).

GROUPS OF EXPLOSION-PROF DEVICES:

|

GROUP

|

DESCRIPTION

|

|

I

|

device intended for use in mining plants, where there is a methane hazard or a coal dust explosion hazard |

|

II

|

device intended for use in places at risk of explosive atmospheres other than mining plants |

CATEGORIES OF EXPLOSION-PROOF DEVICES WITH REGARD TO THE ZONE OF EXPLOSION OF GAS, VAPOR AND FLAME OF FLAMABLE FLUIDS WITH AIR

|

CATEGORY

|

WORK ATMOSPHERE

|

EX ZONE MARKING

|

ENDANGERED AREA

|

|

1

|

G

|

0

|

occurs constantly, for long periods of time or |

|

2

|

G

|

1

|

may occur during normal operation, |

|

3

|

G

|

2

|

does not occur during normal operation, |

CATEGORIES OF EXPLOSION-PROOF DEVICES WITH REGARD TO THE ZONE OF EXPLOSION OF DUST AND COMBUSTIBLE FIBERS

|

CATEGORY

|

WORK ATMOSPHERE

|

EX ZONE MARKING

|

ENDAGNERED AREA

|

|

1

|

D

|

20

|

occurs constantly, for long periods of time or |

|

2

|

D

|

21

|

may occur during normal operation, |

|

3

|

D

|

22

|

does not occur during normal operation, |

TYPES OF CONSTRUCTION OF DEVICES IN AREA ENDANGERED OF EXPLOSION OF GAS, VAPOR AND MIXTURE OF FLAMMABLE FLUIDS WITH AIR

|

HOUSING TYPE

|

DESCRIPTION

|

PROTECTION DEGREE

|

EX ZONE MARKING

|

EPL

|

|

op is

|

safe optical radiation |

very high

|

0,1,2

|

Gb

|

|

d lub db

|

flameproof construction

|

high

|

1,2

|

|

|

e lub eb

|

reinforced construction

|

|||

|

ib

|

intrinsically safe construction

|

|||

|

mb

|

construction encapsulated with isulating mass

|

|||

|

ic

|

intrinsically safe construction

|

normal

|

2

|

Gc

|

|

mc

|

construction encapsulated with isulating mass

|

|||

|

nA

|

non-sparking device

|

|||

|

nC

|

device with shielded terminals

|

TYPES OF CONSTRUCTION OF DEVICES IN AREA ENDANGERED OF EXPLOSION OF DUST AND COMBUSTIBLE FIBERS

|

HOUSING TYPE

|

DESCRIPTION

|

PROTECTION DEGREE

|

EX ZONE MARKING

|

EPL

|

| op is | safe optical radiation | very high | 20,21,22 | Db |

| tb | ochrona przez obudowę | high |

21,22 | |

| lb | intrinsically safe construction | |||

| mb | protection trough encapsulation | |||

| tc | protection through the housing | normal |

22 | Dc |

| lc | intrinsically safe construction | |||

| mc | protection through encapsulation | |||

| p | protection through hypertension |

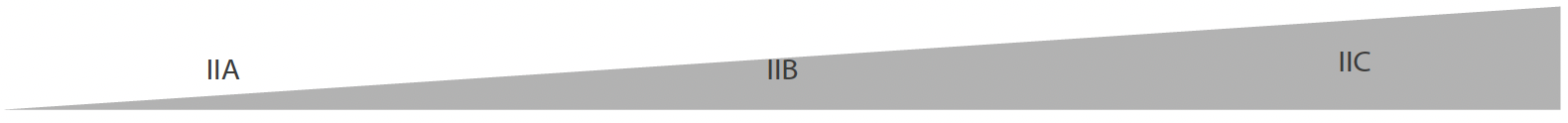

GROUPS OF EXPLOSION GASES VAPORS AND MIXTURE OF FLAMMABLE FLUID WITH AIR

| LEVEL OF PROTECTION | DESCRIPTION | EXAMPLES |

|

IIA

|

propane group |

propane, acetone, benzene, acetic acid, methanol, gasoline, diesel oil, aviation fuel, carbon monoxide |

|

IIB

|

etylen group

|

ethylene, city gas, hydrogen sulphide |

|

IIC

|

hydrogen group

|

hydrogen, acetylene, carbon disulphide |

GROWTH OF EXPLOSION LEVEL

- IIC group devices meet all the requirements for group IIA and IIB equipment

- IIB group devices meet all the requirements for group IIA equipment

GROUPS OF EXPLOSION FOR DUST

| LEVEL OF PROTECTION | DESCRIPTION | EXAMPLES |

|

IIIA

|

volatile combustible dusts |

fiber, wood, paper, cotton

|

|

IIIB

|

volatile non-conductive dusts

|

coal, coke

|

|

IIIC

|

volatile conductive dusts

|

metal filings

|

GROWTH OF EXPLOSION LEVEL

- IIIC group devices meet all the requirements for group IIIA and IIIB equipment

- IIIB group devices meet all the requirements for group IIIA equipment

TEMPERATURE CLASSES OF DEVICES IN AREA ENDANGERED OF EXPLOSION OF GAS, VAPOR AND MIXTURE OF FLUIDS WITH AIR

|

TEMPERATURE CLASS

|

MAXIMUM SURFACE TEMERATURE

|

TEMPERATURE OF SELF-IGNITION OF GAS/VAPOR

|

| T1 | 450OC |

>450OC |

| T2 | 300OC | >300OC |

| T3 | 200OC | >200OC |

| T4 | 135OC | >135OC |

| T5 | 100OC | >100OC |

| T6 | 85OC | >85OC |

THE SCOPE OF APPLICATION OF EQUIPMENT DEPENDING ON THE TEMPERATURE CLASS

TEMPERATURE CLASSES OF DEVICES IN AREA ENDANGERED OF EXPLOSION OF DUST AND COMBUSTIBLE FIBRES

For devices operating in the explosion hazard zone of dust and combustible fibers, the exact maximum temperature on the device surface should be determined [° C]. In the general designation of a series of products, it is permissible to give the temperature range for different versions of the device.

THE MOST COMMON SUBSTANCES WHICH FORM EXPLOSIVE ATMOSPHERE

| GROUP IIA |

GROUP IIB |

GROUP IIC |

|

Methane

Ethane

Propane

Butane

Acetone

Ammonia

Benzene

Carbon Monoxide

Toluene

Acetic Acid

Petrol

n-Haxane

Aviation Kerosene

Diesel

Heating Oil

|

Coke Oven Gas

Ethylene

Ethylene Oxide

Propylene Oxide

Crotonaldehyde

Hydrogen Sulfide

Ethyl Ether

|

Hydrogen

Acetylene

Carbon Disulphide

|

IGNITION TEMPERATURE OF EXEMPLARY EXPLOSIVE ATMOSPHERE SUBSTATION MAKE

| GAS |

IGNITION TEMP. oC |

|

Acetone

|

465 |

|

Benzene

|

498 |

| Butane | 287 |

| Ethane | 472 |

| Ethanol | 363 |

| Petrol | 280 |

| Hexane | 223 |

| Methane | 537 |

| Propane | 432 |

| Propylene | 455 |

| Styrene | 490 |

| Toluene | 480 |

| Hydrogen Disulfide | 260 |

| METALIC DUSTS |

IGNITION TEMP. oC |

|

| Cloud | Layer | |

|

Aluminum

|

650 | 760 |

|

Magnesium

|

620 | 490 |

| Titanium | 330 | 510 |

| Zinc | 630 | 430 |

| Bronze | 370 | 190 |

| Chrome | 580 | 400 |

| Copper | 630 | 430 |

| Cadmium | 570 | 250 |

| FIBRE |

IGNITION TEMP. oC |

|

| Cloud | Layer | |

|

Cotton lint

|

520 | - |

| Flax | 430 | 230 |

| Rayon | 520 | 250 |

| NON-METALIC DUSTS |

IGNITION TEMP. oC |

|

| Cloud | Layer | |

|

Cocoa

|

420 | 200 |

|

Coffee

|

410 | 220 |

|

Corn dust

|

400 | 250 |

|

Sugar

|

350 | 400 |

|

Corn

|

480 | 220 |

|

Flour

|

480 | 220 |

|

Nylon

|

500 | 430 |

|

Polyethylene

|

450 | 380 |

|

Coal dust

|

610 | 180 |